Why Filtration Technology is Key to Building a Sustainable Energy Future

Filtration technology is at the heart of sustainable energy operations. Whether in natural gas processing or renewable energy systems, effective filtration helps reduce emissions, protect equipment, and support cleaner energy production. In the United States, particularly in energy hubs like Texas, industries rely on advanced gas filter separators and liquid filter separators to remove contaminants from natural gas and other fuel sources. These filter separators in the USA play a critical role in ensuring energy efficiency while minimizing environmental impact.

How Filter Separators Improve Energy Efficiency

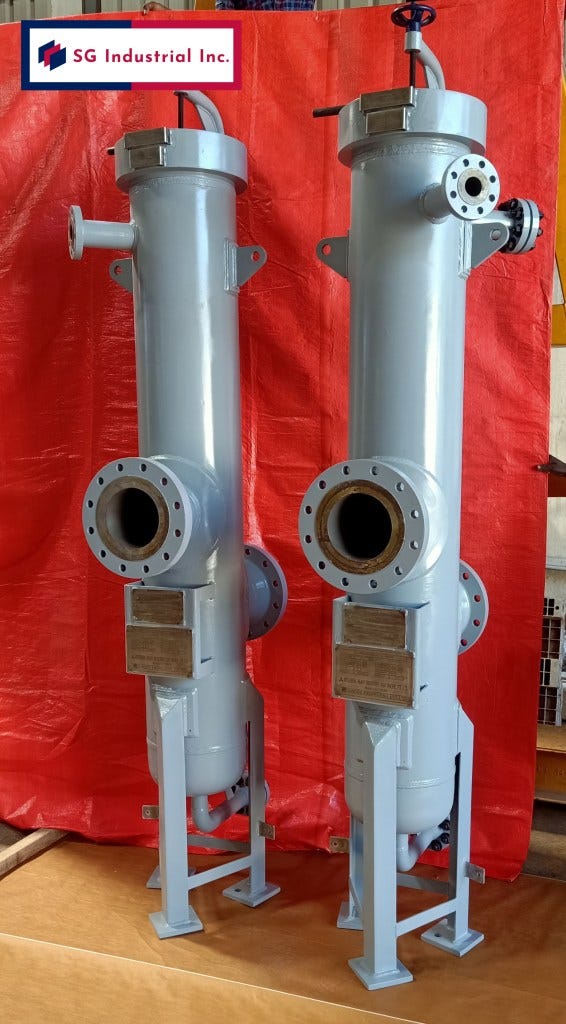

In the natural gas sector, gas filter separators are essential for eliminating dust, moisture, and solid particles from gas streams. These impurities, if left untreated, can damage equipment, reduce fuel quality, and increase emissions. Both vertical filter separators and horizontal filter separators are used based on space availability and capacity needs. Vertical separators are ideal when space is limited, while horizontal separators can handle higher gas volumes efficiently — something particularly important for operations in energy-driven regions like Texas.

By improving filtration performance, these separators support cleaner gas production, extend equipment life, and help reduce the carbon footprint of industrial operations.

Filtration’s Role in Renewable Energy Systems

Beyond natural gas, filtration plays an equally vital role in renewable energy systems. In wind energy projects, filtration systems prevent dust and moisture from damaging turbines, ensuring reliable performance. Solar energy systems also benefit from clean water filtration, which prevents dirt accumulation on solar panels and maintains energy output.

In bioenergy and hydrogen production, filtration removes impurities from feedstock and gases, enabling cleaner combustion and higher-quality fuel. These advanced liquid filter separators and gas filters are essential for maintaining operational efficiency while supporting the broader shift toward renewable energy in the USA.

Filtration in Hydrogen and Carbon Capture Technologies

Filtration technology is also fundamental to emerging clean energy solutions such as hydrogen production and carbon capture. During hydrogen production, it’s critical to remove particulates, oil, and moisture from feed gases to avoid damage to electrolyzers and fuel cells. High-efficiency gas filter separators are used to ensure hydrogen purity, which is crucial for sustainable industrial applications.

In carbon capture systems, filtration helps remove dust and other impurities before the gas enters the capture process. This improves efficiency, reduces equipment wear, and supports efforts to lower greenhouse gas emissions. Across projects in Texas and other parts of the USA, filtration systems are helping industries transition to cleaner, low-carbon energy models.

Driving Sustainable Solutions with Filter Separator Innovation

Innovations in filtration technology are making a measurable difference in reducing emissions and improving operational efficiency. Modern filter separators in the USA now include advanced materials such as nanofiber filters and self-cleaning mechanisms, helping industries capture even the smallest contaminants while lowering energy consumption.

Many Texas-based industries are adopting smart filtration systems that offer real-time monitoring and predictive maintenance, leading to reduced downtime and better compliance with environmental regulations.

Choosing the Right Filter Separators for Sustainable Operations

Selecting the right filtration solutions is critical to achieving sustainability goals. Industries operating in natural gas, renewable energy, or hydrogen production must invest in advanced filter separators USA solutions tailored to their specific operational needs. Factors like flow rate, type of contaminants, and local regulations — particularly in energy-centric regions such as Texas — must be considered while choosing the appropriate gas filter separators or liquid filter separators.

By adopting the right filtration technologies, industries can improve efficiency, reduce emissions, and contribute to a greener, more sustainable energy future.

Comments

Post a Comment